Page 1 of 1

Help With Oak Finish on Victrola XI's and X's

Posted: Sat Apr 20, 2013 2:56 pm

by Couch Potato

I have several Victrola's that clearly left the factory with a Golden Oak type finish but do not seem to have had shellac on them at any point. So for you factory finish experts out there my question is what is the original finishing method at the factory? Were these simply stained? Were they simply stained and perhaps paste waxed? Did they get a very light coat of shellac or varnish what was then almost compete buffed off? Wonder how these were done a the factory?

Of course the machines I have are close to 100 years old so there is not telling what happened to them during that time. The ones I have are much lighter in color on the inside doors and under the lid and motor boards and in those areas seem pretty much untouched since the teens. The outside areas are typically much darker I assume the result of sunlight, more exposure to contaminates, and the well meaning furniture polish and was mostly like applied by earlier. owners. In the past I have cleaned such machines with gojo or lemon oil and slight steel wool rubbing resulting in the removal of all the grime and nasty which seems to result in a some what lighter then beginning state result.

Not sure if that is the best method for reviving this finish. Perhaps there is a better method for reviving this finish? But again very much wondering what exactly the finish was to begin with?

Have been wary of paste waxing such a finish for fear of doing some un-reverseable, but am wonder if that is in fact what was done at the factory on these.

Any thoughts out there on this?

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sat Apr 20, 2013 3:41 pm

by phonogfp

As you know, Victor offered a number of oak finishes and very thoughtlessly (for future collectors) failed to note what they were on the individual machines! When a relatively light oak finish is encountered, and lacks the gloss associated with shellac, my first suspicion is Fumed Oak, which was finished off with wax. Here's an earlier thread showing a Fumed Oak Victrola:

http://forum.talkingmachine.info/viewto ... oak#p57320

There were other waxed oak finishes, but Fumed seems to have been quite popular at the time.

George P.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sat Apr 20, 2013 10:03 pm

by Couch Potato

George, thank you for the link to the other thread. This makes me feel pretty comfortable that I have two Fumed Oak machines. It does not seem these are easily cleaner or spruced up. Sure these machines must have been very nice when new. Mine are just both dark on the outside. Sounds like there is no practical way to really revive them. Suppose a very light cleaning with what I am not sure followed by a light past waxing is perhaps most appropriate.

Those earlier pictures you posted where very help as they are the exact finish I am dealing with. I take it that crate and machine have the same serial number? If so that someone has a machine and the matching original crate is really amazing.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sat Apr 20, 2013 10:16 pm

by Jerry B.

I've seen golden oak finishes that appeared to be without a finish coat of shellac. I assumed they were just waxed. Did they reach that appearance by a fumed oak process? I checked the previous thread and the finish appeared much darker. Thanks, Jerry

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 11:52 am

by phonogfp

Jerry B. wrote:I've seen golden oak finishes that appeared to be without a finish coat of shellac. I assumed they were just waxed. Did they reach that appearance by a fumed oak process? I checked the previous thread and the finish appeared much darker. Thanks, Jerry

Couch: Yes the serial number on the machine and the crate match. That's the only way I could be sure that the machine really had a Fumed Oak finish. You can see the machine's serial number by clicking on the image and then clicking it again to enlarge it.

Jerry: I think we're confusing types of wood and types of finish. There is no "Golden Oak" wood; only when the oak has a light brown stain and a shiny clear finish did Victor call it a "Golden Oak" finish. I believe color variations between other waxed finishes (such as Fumed Oak) are probably due to the application of oils or stains by various owners over the years. Without a protective coat of shellac, these waxed finishes were/are particularly vulnerable to whatever might be applied to them.

George P.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 12:02 pm

by Jerry B.

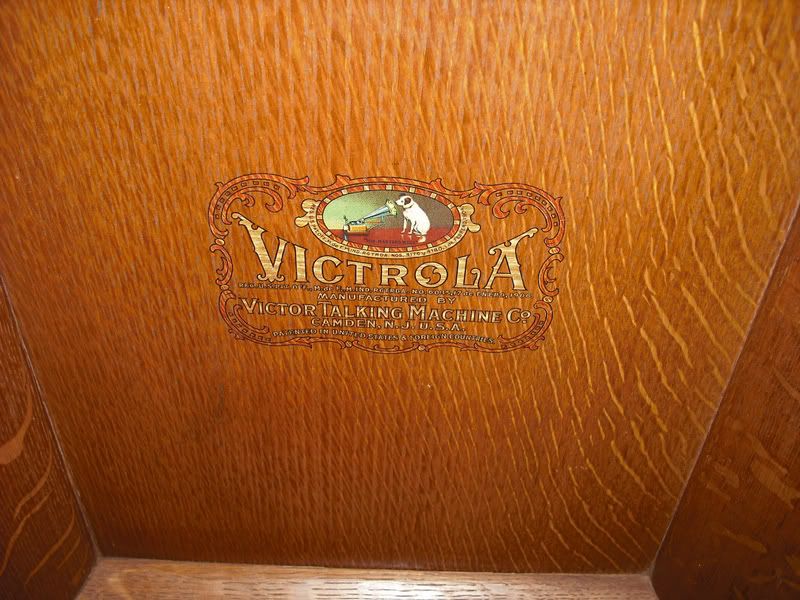

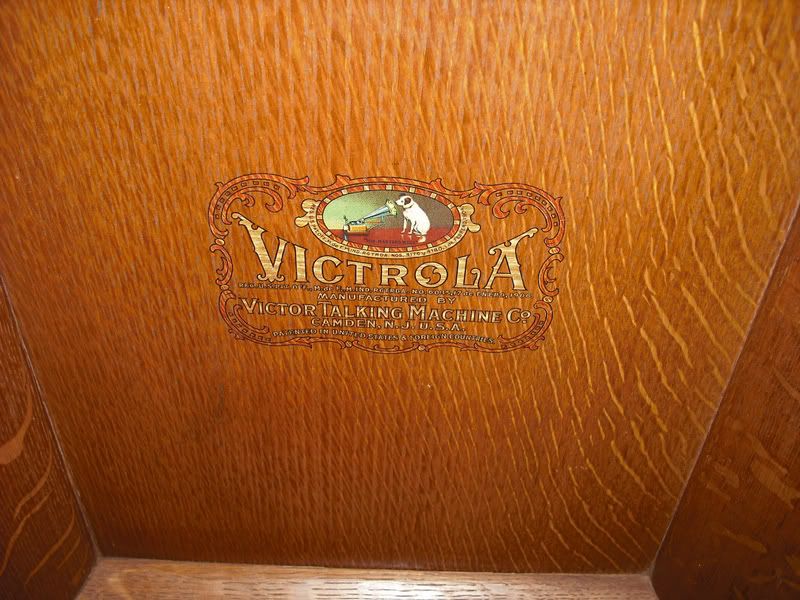

I've seen oak finished in a golden color with and without a shellac top coat. Did the ones that have no apparent shellac finish reach that color by a fumed process or more conventional stain? That's my real question. I always assumed a fumed oak had a darker color. If a refinished machine still has the original decal, you can look through the decal to see the original color. The machine at the top of this thread appears light in color through the decal. Thanks, in my opinion this is very interesting. Jerry

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 12:07 pm

by phonogfp

Jerry B. wrote:I've seen oak finished in a golden color with and without a shellac top coat. Did the ones that have no apparent shellac finish reach that color by a fumed process or more conventional stain? That's my real question. I always assumed a fumed oak had a darker color. If a refinished machine still has the original decal, you can look through the decal to see the original color. The machine at the top of this thread appears light in color through the decal. Thanks, in my opinion this is very interesting. Jerry

Jerry, it beats me. I presume that some of the many oak finishes Victor offered were done by stain, others by fuming, and others by rubbing with oil. If only the finish had been noted on each machine!

George P.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 12:26 pm

by Uncle Vanya

These light fumed oak machines were given a wash of thinned, refined and de-waxed white shellac, of about a ¾ or one pound cut, to seal the surface of the wood and offer a surface for the wax, and to prevent the oils in the wax from further darkening the grain of the wood. This surface was the rubbed down with dried seaweed to dull the surface and partly fill the depths of the oak grain before a very light, refined hard wax was applied as the finish.

Here are some snaps of a VV-IX in this finish that I restored some years ago. The decal is a reproduction, one of the rub-on units from Decals Unlimited. This machine had been given the Formby's Golden Oak treatment. I cleaned , stripped and lightly sanded the wood surface, and fumed the cabinet pieces in an old tent with several bowls of agricultural anhydrous ammonia set about. This stuff has become difficult to acquire now that it is known to be used by drug makers and bomb-builders, but a couple of quarts may usually be obtained if you well cultivate your local farm supply dealer.

The finished job:

I worked hard to match the untouched finish on the horn, and believe that I did a creditable job, though not quite perfect. My poor flash photography distorts the color of the machine, which is considerably more uniform and less yellow.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 3:51 pm

by Couch Potato

That table top IX is pretty darn nice looking. Very interesting order of work done to it. Don't live near the beach but have read before Victor favored the seaweed. Maybe need to acquire some and do some experiments using it.

Re: Help With Oak Finish on Victrola XI's and X's

Posted: Sun Apr 21, 2013 5:02 pm

by Uncle Vanya

The "Seaweed" that you want is actually a red algae known colloquially as "Irish Moss" (no, NOT the landscape ground cover which is so named!). "Irish Moss" is mildly abrasive, and contains 55% by weight Carragean, which is what does the job as the grain filler. This algae is also used extensively in cooking, as the traditional thickener for Blanc Mange and various sauces and confections.